Hanging 1150mm Cooling Tower Fill Types PVC Fill For Cooling Tower

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | XL |

| Certification: | SGS |

| Model Number: | XL-1150mm-EAC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10/square meters |

|---|---|

| Price: | $1.6-2/ meters |

| Packaging Details: | Wooden,cartons,custom package |

| Delivery Time: | 10 working days |

| Payment Terms: | Western Union, T/T, MoneyGram, D/P, D/A, L/C |

| Supply Ability: | 1000M/per pay |

|

Detail Information |

|||

| Cooling Type: | Cooling Tower Parts | Material: | PVC,CPVC |

|---|---|---|---|

| Warranty: | 1 Year | Name: | Hanging 1150mm Width Cooling Pads PVC Fill For Cooling Tower |

| Width: | 1150mm | Length: | 2440mm/customized |

| Sheet Spacing: | 20mm | Usage: | Cooling Tower |

| MOQ: | 10/square Meters | Material Thickness: | 0.38-0.6mm |

| Highlight: | 1150mm Cooling Tower Fill Types xianglong,Cooling Tower Fill Types PVC Fill xianglong,PVC Fill For Cooling Tower xianglong |

||

Product Description

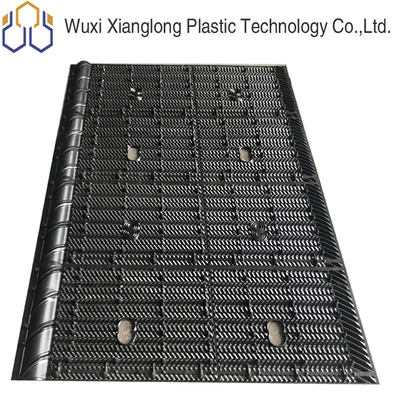

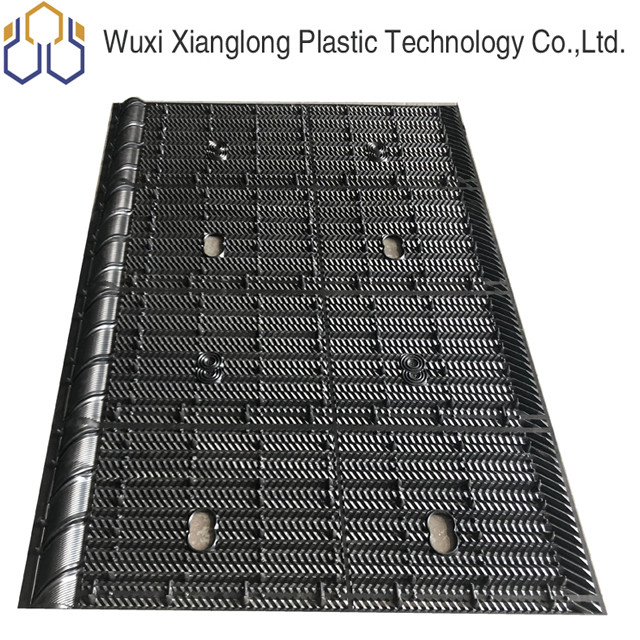

Hanging 1150mm width Cooling Pads PVC Fill for Cooling Tower

Specifications:

| Tech Date | |

| Sheet Width(mm) | 1150mm |

| Sheet Length | 2440mm/customized |

| Thickness | 0.38-0.6mm/customized |

| Sheet Spacing | 20mm |

| Color | grey/black |

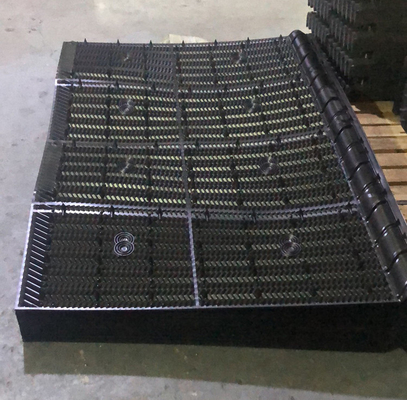

The principle of operation of cooling tower fill is to put as much water surface area in contact with as much air as possible, for the longest amount of time possible. Film fills allow the water to form thin flowing sheets to expose as much water surface area as possible to the interacting flow.

Cooling tower sheet fills or media, come in many different forms and "micro-structures," each having unique characteristics to fit various applications. Film fills are selected for direct replacement, performance enhancement, and water condition compatibility. Each fill has performance characteristics that allow selections to be made for various heat loads, flow rates, water quality, and horse power combinations.

Related Cooling Tower Film Fill

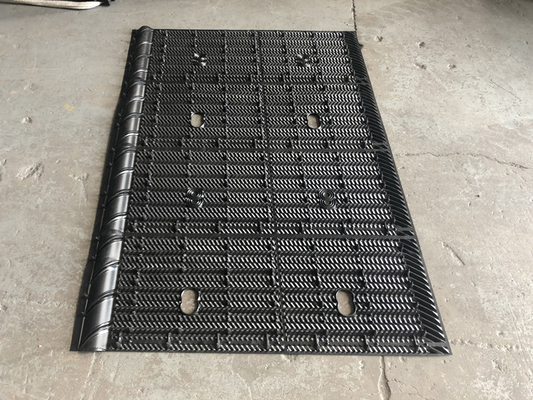

• Outstanding thermal performance, will meet or exceed the performance of any OEM fill

• Unique method for quick and easy field installation, saves labor

• Nested shipment requires smallest fill staging area and low shipping costs

• Model-specific kits contain everything needed for an efficient installation, including detailed instructions, supports, hardware, and fill

• 2-week standard lead time

PACKING AND DELIVERY

![]()