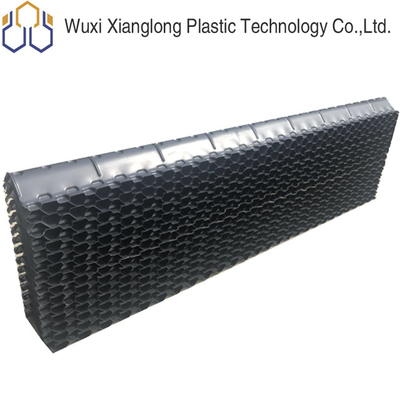

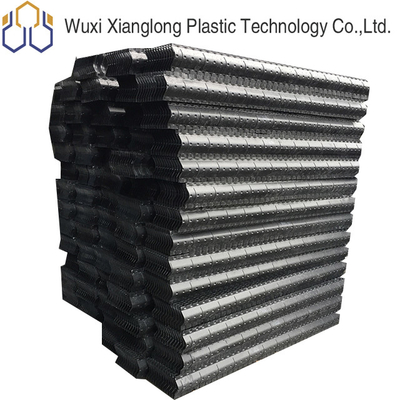

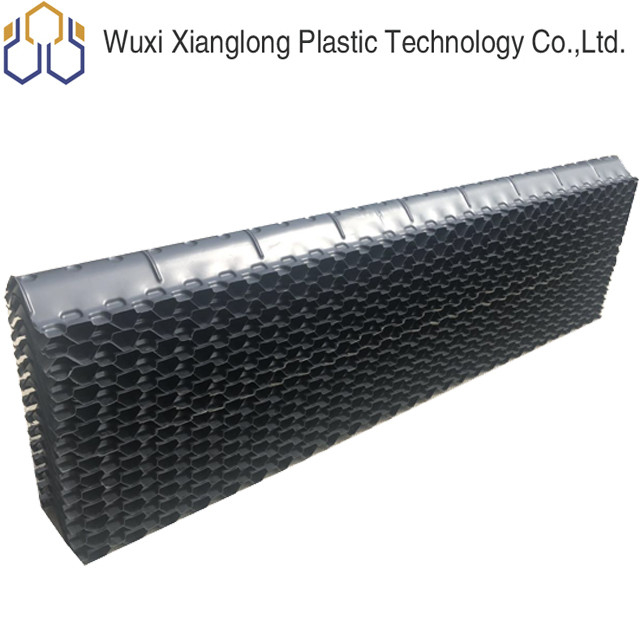

Cross Flow Wave PVC Drift Eliminator Fill Module For Cooling Tower

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | XL |

| Certification: | SGS |

| Model Number: | XL-Evapco-145MM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 square meters |

|---|---|

| Price: | $20-30/square meters |

| Packaging Details: | Wooden,cartons,custom package |

| Delivery Time: | 10 working days |

| Payment Terms: | Western Union, T/T, MoneyGram, D/P, D/A, L/C |

| Supply Ability: | 1000m2/per pay |

|

Detail Information |

|||

| Cooling Type: | Cooling Tower Parts | Material: | PVC,PP,CPVC |

|---|---|---|---|

| Warranty: | 1 Year | Name: | Cross Flow Wave PVC Drift Eliminator PVC Fill Module For Cooling Tower Eliminator |

| Width: | 140-145mm | Product Name: | Drift Eliminator |

| Sheet Spacing: | 25mm | Usage: | Cooling Tower |

| MOQ: | 10 Square Meters | Thickness: | 0.6mm |

| Highlight: | Cross Flow Wave PVC Drift Eliminator,PVC Drift Eliminator Fill Module,Cooling Tower PVC Drift Eliminator |

||

Product Description

Cross flow wave PVC drift eliminator PVC Fill Module for cooling tower eliminator

Description:

Drift Eliminators, made out of rigid PVC, are designed to remove entrained particles from air steam efficiently, with minimum pressure drop, thereby reducing the fan power requirement when the air passes through the Drift Eliminator. Water droplets are separated from the air drift at the three direction change points on the drift eliminator.For Cross flow tower applications, the almost vertical water conduits provided by the DE drift eliminator remove the water droplets out of the drift eliminator area and return them back into the tower and does not allow any re-entry.The special locking pin arrangement for DE facilitates quick and simple assembly at site.

Specifications:

| Tech Date | |

| Sheet Width(mm) | 140-145mm |

| Sheet Length | 1220mm/1830mm/customized |

| Thickness | 0.38-0.6mm/customized |

| Sheet Spacing | 25mm |

| Color | black |

![]()

![]()

Product process

Related Blade Drift Eliminator

Drift eliminator advantages:

1. Maximum drift capture through efficient design

2. Light weight

3. Easy to handle, lift and remove for inspection and service of water distribution system and heat transfer surface (fill and coil)

4. Nested modules to guarantee watertight seam

5. Corrosion free

6. Perfect fit: model specific size kits

PACKING AND DELIVERY

![]()