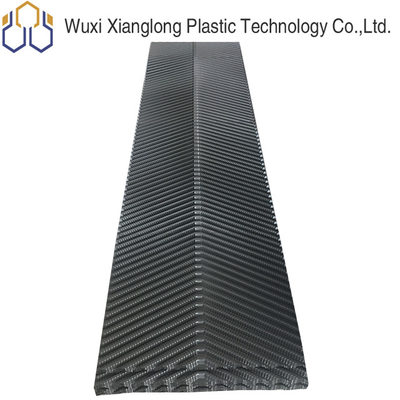

Cooling Tower PVC fill Sheet Counterflow Filler 610mm Cooling Tower Filing Pack

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | XL |

| Certification: | SGS |

| Model Number: | XL-610-VF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 square meters |

|---|---|

| Price: | $1.2-2/square meters |

| Packaging Details: | Wooden,cartons,custom package |

| Delivery Time: | 10 working days |

| Payment Terms: | Western Union, T/T, MoneyGram, D/P, D/A, L/C |

| Supply Ability: | 1000m2/per pay |

|

Detail Information |

|||

| Name: | 19mm Sheet Space 610mm Counter Flow Cooling Tower PVC Fills For Cooling Tower | Condition: | New |

|---|---|---|---|

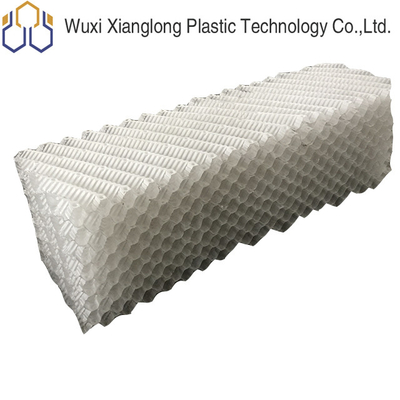

| Cooling Type: | Cooling Tower Parts | Material: | PVC,PP,CPVC |

| Warranty: | 1 Year | Width: | 305/610mm |

| Length: | 1220/1830/2440/customized | Usage: | Cooing Tower |

| MOQ: | 10 Square Meters | Thickness: | 0.32-0.6mm |

| Wave Height: | 12/15/19/30mm | ||

| Highlight: | 610mm Cooling Tower Fill Sheet,Counterflow Cooling Tower Fill Sheet,PVC Cooling Tower Fill Sheet |

||

Product Description

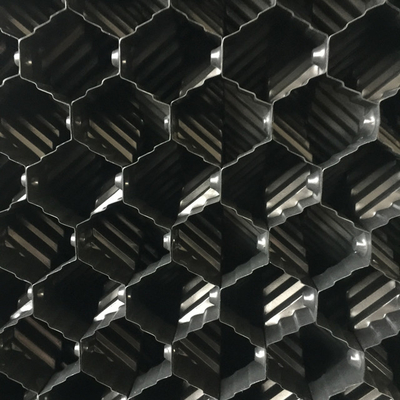

Cooling Tower PVC fill Sheet Counterflow Filler 610mm Cooling Tower Filing Pack

Types of fills in cooling tower

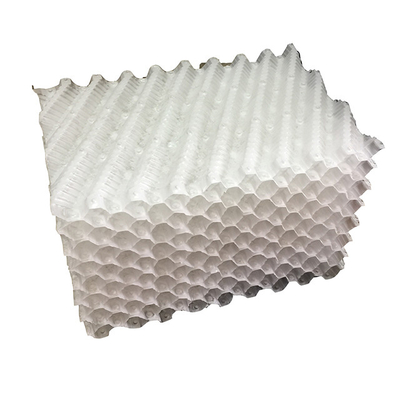

There are two common types of fill media, splash fill and film fill.

Splash fill media were traditionally made from wood, but modern cooling tower fill material is made from PVC. PVC is more efficient as it facilitates better heat transfer. A big advantage of splash fill is that it’s very forgiving of insufficient

initial water distribution, since the splashing activity redistributes the water at each level of splash bars. Because of this, a cooling tower with splash fill effectively handles water containing debris. Maintenance is also easier, because its open nature offers easy visual inspection of the water flow pattern and the condition of the fill.

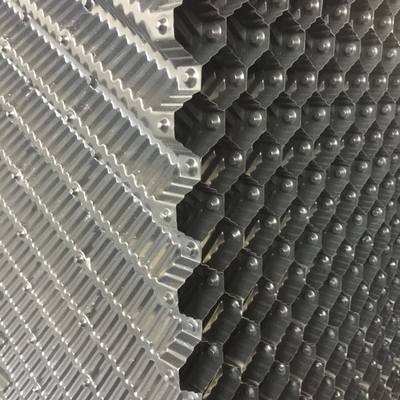

Specifications:

|

Tech Date |

|

|

Sheet Width(mm) |

305/610mm |

|

Sheet Length |

1220/1830/2440mm/customized |

|

Thickness |

0.32-0.6mm/customized |

|

Sheet Spacing |

12/15/19/30mm |

|

Color |

grey/white/black |

|

Material |

PP/PVC/ CPVC |

![]()

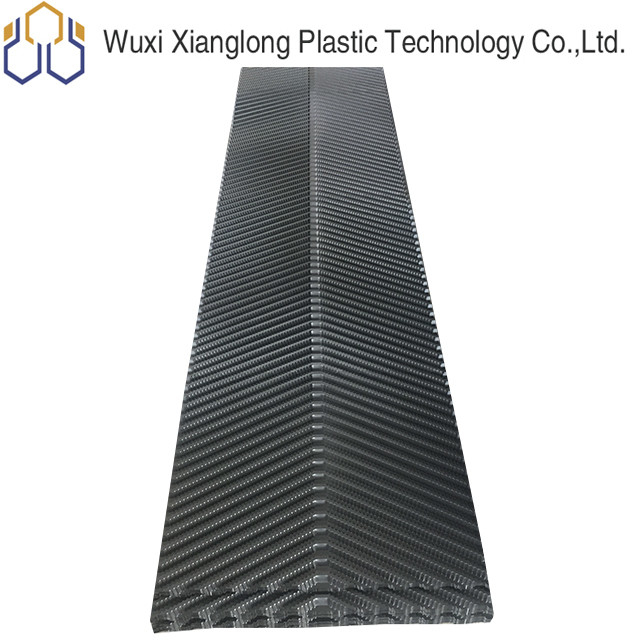

Cooling Tower Fill Operating of Principle

*Cooling towers reject heat from water-cooled systems to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which is collected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

*There are two main configurations of factory assembled cooling towers: crossflow and counterflow. In crossflow cooling towers, the water flows vertically down the fill as air flows horizontally across. In counterflow cooling towers, the water flows vertically down the fill as air flows vertically up.

Related Cooling Tower Film Fill

![]()

Supply in industry

![]()

How do fills work in the cooling tower?

Cooling towers reject heat from water-cooled system to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which iscollected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

PACKING AND DELIVERY

![]()

![]()

![]()

![]()

![]()

About US

![]()

![]()

![]()