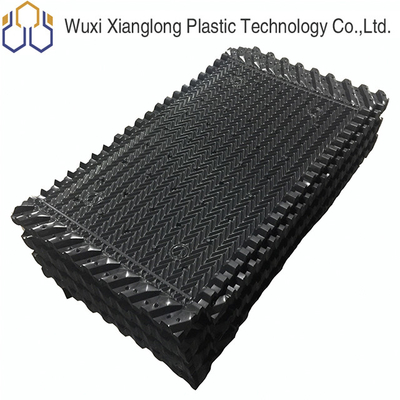

Cross Flow PVC Black Cooling Tower Media Cooling Tower Packing Material

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | XL |

| Certification: | SGS |

| Model Number: | XL-1520 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 square meters |

|---|---|

| Price: | $1.2-2/square meters |

| Packaging Details: | Wooden,cartons,custom package |

| Delivery Time: | 10 working days |

| Payment Terms: | Western Union, T/T, MoneyGram, D/P, D/A, L/C |

| Supply Ability: | 1000m2/per pay |

|

Detail Information |

|||

| Condition: | New | Cooling Type: | Cooling Tower Parts |

|---|---|---|---|

| Material: | PVC,PP,CPVC | Warranty: | 1 Year |

| Name: | Cooling Tower Fills For Hot Water Distribution In Tower Cross Flow Cooling Tower PVC Fill With Drift Eliminator | Width: | 1520/1400/1350/1230/1100/1000/900/850mm |

| Height: | 500/620mm | Usage: | Cooing Tower |

| MOQ: | 10 Square Meters | Thickness: | 0.32-0.6mm |

| Wave Height: | 19mm | ||

| Highlight: | PVC Black cooling tower media,Cross Flow cooling tower media,cooling tower packing material |

||

Product Description

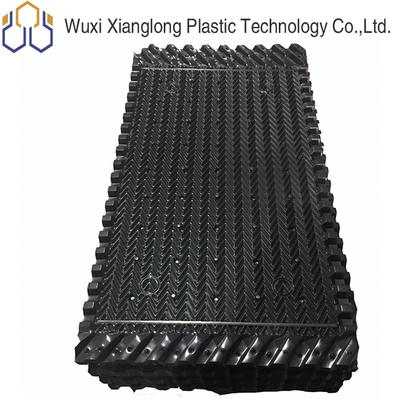

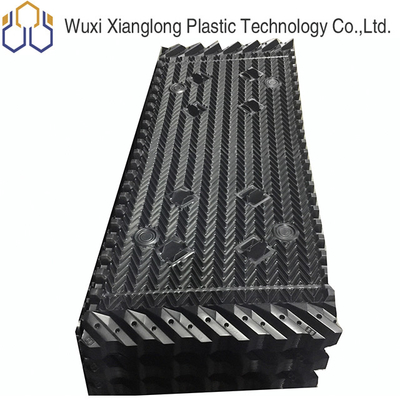

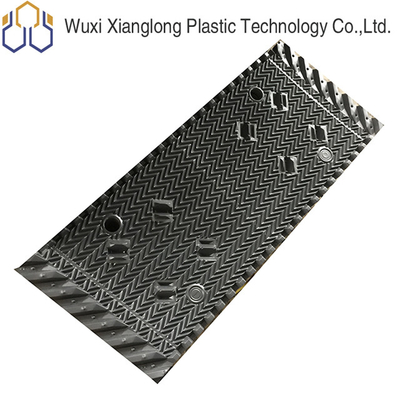

High quality cross flow pvc black filling sheet media cooling tower fill packing

Description:

1. Bevel Tips promotes drainage at fill pack interfaces.

Note: Packs are always installed with Bevel Tips at bottom of pack.

2. Patented "MA" (Mechanical Assembly) Technology for glue-free packs.

3. Engineered microstructure for improved water distribution and thermal mixing.

4. High thermal performance

5. Improved water distribution

6. Proprietary edge trim that directs water to both sides of sheet

7. Available in PVC

Specifications:

|

Tech Date |

|

|

Sheet Width(mm) |

15020/1400/1350/1230/1100/1000/900/850mm |

|

Sheet Length |

620/500mm/customized |

|

Thickness |

0.32-0.6mm/customized |

|

Sheet Spacing |

19-20mm |

|

Color |

grey/white/black |

|

Material |

PP/PVC/CPVC |

Cooling Tower Fill Operating of Principle

*Cooling towers reject heat from water-cooled systems to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which is collected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

*There are two main configurations of factory assembled cooling towers: crossflow and counterflow. In crossflow cooling towers, the water flows vertically down the fill as air flows horizontally across. In counterflow cooling towers, the water flows vertically down the fill as air flows vertically up.

Related Cooling Tower Film Fill

![]()

Supply in industry

![]()

How do fills work in the cooling tower?

Cooling towers reject heat from water-cooled system to the atmosphere. Hot water from the system enters the cooling tower and is distributed over the fill (heat transfer surface). Air is induced or forced through the fill, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which iscollected in the cold water basin and returned to the system to absorb more heat. Each cooling tower line, although operating under the same basic principle of operation, is arranged a little differently.

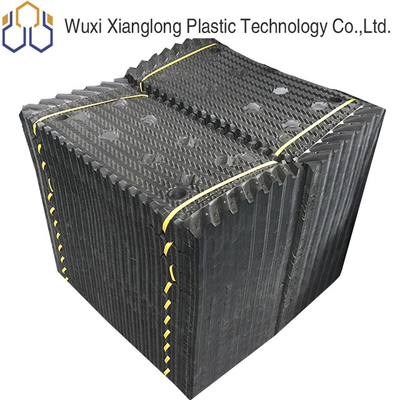

PACKING AND DELIVERY

![]()

![]()

![]()

![]()

![]()

About US

![]()

![]()

![]()

![]()

Q: Are you trading company or manufacturer ?

A: We are manufacturer with our own factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge. And the freight cost will on the buyer's side.

Q: What is your terms of payment ?

A: Payment<=USD1000, 100% in advance. Payment>=USD1000, 30% T/T in advance ,balance before shipment.