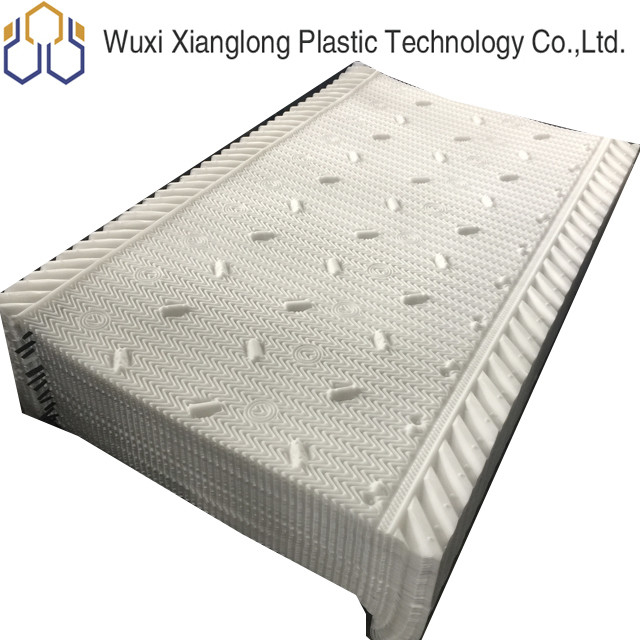

19mm Cooling Tower Plastic Fill 0.5mm Thickness Cooling Tower Fill Media

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | XL |

| Certification: | SGS |

| Model Number: | XL-1220-MA |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 square meters |

|---|---|

| Price: | $1.2-2/square meters |

| Packaging Details: | Wooden,cartons,custom package |

| Delivery Time: | 10 working days |

| Payment Terms: | Western Union, T/T, MoneyGram, D/P, D/A, L/C |

| Supply Ability: | 1000m2/per pay |

|

Detail Information |

|||

| Condition: | New PP Material | Cooling Type: | Cooling Tower Parts |

|---|---|---|---|

| Material: | PVC,PP,CPVC | Warranty: | 1 Year |

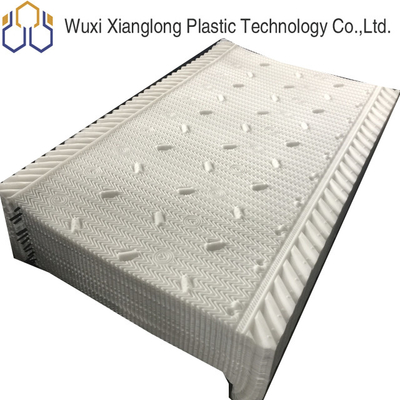

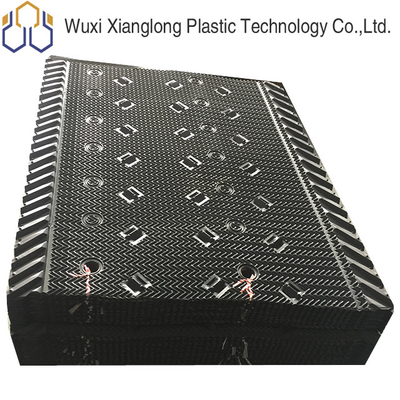

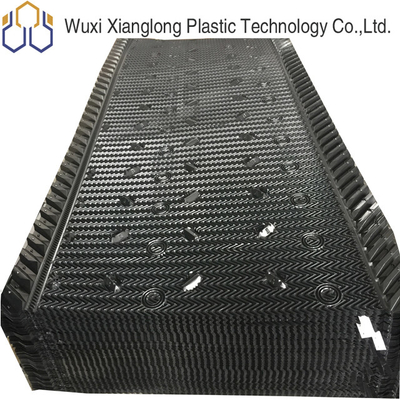

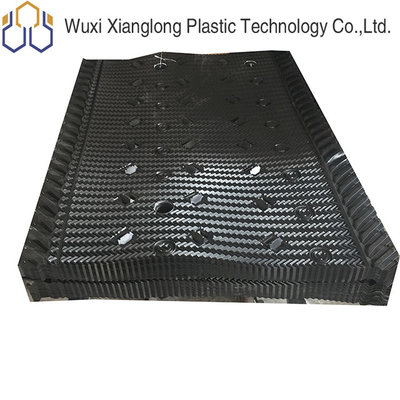

| Name: | Wave Depth 19mm Cooling Tower Fill PP Material 0.5mm Thickness Cooling Tower Fill Media | Width: | 750/820/920/1020/1220/1520mm |

| Wave Height: | 19-20mm | Usage: | Cooing Tower |

| MOQ: | 10 Square Meters | Thickness: | 0.32-0.6mm |

| Highlight: | 19mm Cooling Tower Plastic Fill,Cooling Tower Plastic Fill 0.5mm,cooling tower fill media SGS |

||

Product Description

Wave depth 19mm cooling tower fill PP material 0.5mm thickness cooling tower fill media

Description:

* The material used for the ML cooling tower filler is PVC/PP/ CPVC. The purpose of the filler is to increase the viscosity of the product, especially the small filler to increase the viscosity significantly. ML cooling tower fill before accumulation is subject to dehydration sale to avoid consuming some of the isocyanate. It must be noted that the changeable carbon anhydride will cause the resin to foam, which will deter the physical properties of the polyurethane resin.

* In order to speed up the wetting speed of ML cooling tower fill and reduce system viscosity. Still more and more fillers are increasing in the polyurethane resin, sometimes it is necessary to add a wetting and wetting dispersant in the resin in advance. In-mold paint is an additive with three benefits of coating, colorant and release agent.

* The ML cooling tower filler is evenly burst into the mold, and after the paint film is dried, the polyurethane sole, self-skin foam, and polyurethane soft foam can be molded. necessary products. If the envoy wants to say that the quality of the filling habits is determined, it still depends on the following aspects:

① ML cooling tower packing has a larger specific surface area (m2/m3 packing layer);

② ML cooling tower filler liquid has better mechanical properties of uniform distribution on the surface of the filler;

③ The packing airflow of Marley cooling tower can be evenly distributed in the packing layer;

④ ML cooling tower packing material is not without large porosity (m3/m3 packing layer). There are other caves, and factors such as its doctrinal strength, origin, artificiality and price should also be considered when choosing fillers carefully.

Specifications:

| Tech Date | |

| Sheet Width(mm) | 1220mm |

| Sheet Length | 206MM*N(N=4,5,6,7,8,9,10,11,12......)/customized |

| Thickness | 0.32-0.6mm/customized |

| Sheet Spacing | 19-20mm |

| Color | grey/white/black |

| Material | PP/PVC/CPVC |

![]()

![]()

Related Cooling Tower Film Fill

Cleaning Cooling Tower Tips

Cooling tower packing cleaning method:

1. Manual cleaning of the slag falling off in the cooling tower;

2. Rinse the packing repeatedly with a high-pressure water gun to remove the sludge and scale under cleaning;

3. Dissolve the TNB descaling agent with hot water at about 50°C, and then use the flushing pump to rinse the filler repeatedly until the scale is rinsed off (if the filler has a long service life, causing aging and collapse, it is recommended to replace the filler), and add algaecide at the same time. Completely kill biological algae and;

4. After confirming that all parts of the system are cleaned, drain the sewage;

5. Rinse the packing and the inside and outside of the tower body with clean water;

6. Restore all parts of the system, replenish water and use it;

7. After all recovery, please check and accept the management personnel of Party A;

8. Evacuate Party B's belongings and clean the site;

PACKING AND DELIVERY

![]()

![]()

![]()

About US

![]()

![]()